Endotoxin dashboard developed for air quality in poultry houses

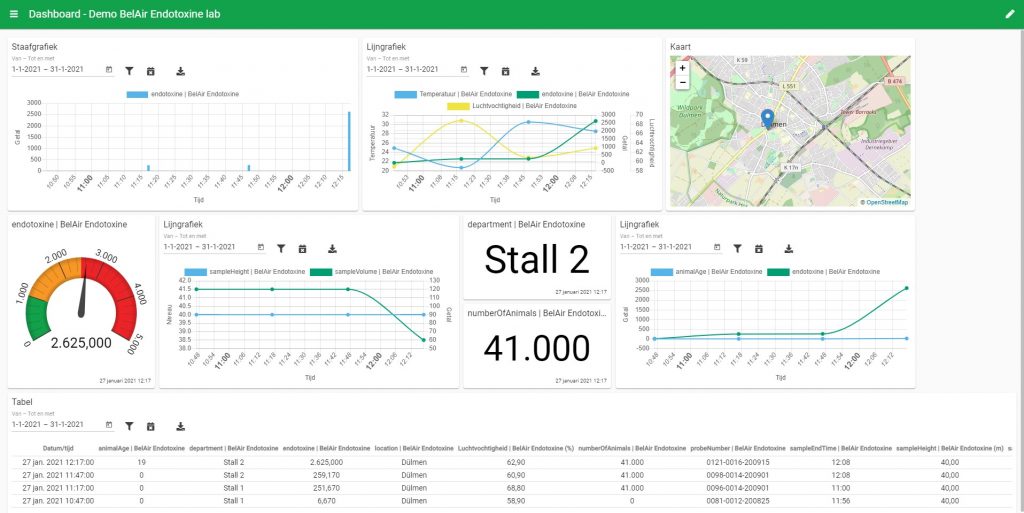

InWithin the German-Dutch INTERREG project BEL AIR, in which solutions for clean and healthy air in poultry farms are being developed, the eleven project partners carried out numerous sampling and air measurements and tested air purification technologies. In parallel, the project partner Whysor B.V. set up a data cloud into which all data measured in the project flow so that they can be better analysed and compared. The results of the measurements and sampling are visualised in a BEL AIR dashboard developed by Whysor, which makes it possible for each test barn to read directly via computer, tablet or smartphone what the current climate and air pollution in the barn is and how it is developing.

For this purpose, various sensors were installed in several test barns in the German-Dutch border area, networked and connected to the internet. All sensors functioned without any problems despite the high concentrations of particulate matter in poultry farms compared to other animal species. Values such as fine dust, temperature, ammonia, CO2, humidity and wind speed were measured – the latter was necessary for the interpretation of the fine dust sensor, as it was operated in a special wind tunnel. “As with other species, the sensors need to be hung out of reach of the animals. In the case of the broilers, this was several metres above the animals. Also – except for the fine dust measurement – it was not allowed to measure in the direct air flow of the incoming and outgoing air,” says project manager Imke Hermens from Whysor.

The dashboard gives farmers a whole new view of their barns

If the measured values turn out to be above average, this is directly indicated to the user by a red traffic light on the dashboard. The effects of the activities of the normal daily routine in the barn can thus be tracked live on the dashboard and – if necessary – appropriate measures can be taken: “On poultry farms, clear daily patterns can be recognised alongside those of an entire fattening cycle,” says Angela van der Sanden, expert in innovative barn systems and data analysis at BEL AIR partner DLV Advies. “This gives insight into the effects of certain activities within the barn – such as mucking out or adjusting to the ventilation system – on the barn climate as well as particulate matter and endotoxin levels,” van der Sanden continues. Problems can thus be quickly located and addressed by looking at the graphically and practically prepared data.

The architecture behind the dashboard and cloud, which was programmed by Whysor and developed with other partners such as DLV Advies, is called “Smart Barn” and has been further developed in other projects besides BEL AIR, such as Food Pro-tec-ts (here specifically for pig houses). The special feature of the BEL AIR project was the integration of endotoxin measurements into the dashboard. The sampling and analysis of endotoxin samples to measure the endotoxin load in the stables, which is carried out by random sampling, cannot be done live compared to the other values and therefore only appears in the dashboard with some delay. This originally analogue process, which was done on paper, has now been digitised in BEL AIR. Whysor has developed two apps for this – one for calibrating the sensors and one for sampling, where measured values and boundary conditions can be recorded during the measurement moment. The values are then also transmitted to the BEL AIR cloud and also help to identify a possible link between the endotoxin values and the measured values of the other sensors.

Rule creation and integration into existing barn computers

IIn the remaining months of the project until the end of March 2022, rules are to be developed within BEL AIR on the basis of the data and measurements obtained, so that in the case of certain patterns, automated notifications are generated which In the remaining months of the project until the end of March 2022, rules are to be developed within BEL AIR on the basis of the data and measurements obtained, so that in the case of certain patterns, automated notifications are generated which inform the poultry farmer and, if necessary, request him to take further measures. To this end, the previous measurement results are first to be further interpreted and correlated with each other. Another challenge that is being addressed outside of BEL AIR is the integration of the dashboard into existing barn computer systems. Usually these are closed systems without open interfaces for external systems. In a follow-up project, Whysor, in collaboration with DLV Advies, is already busy developing modules that will enable integration of the barn dashboard into various existing systems.

The BEL AIR project

Within the BEL AIR project, various technologies for the reduction of endotoxin emissions in and outside poultry houses have been (further) developed and tested by German and Dutch partners since the end of 2018. Endotoxins (lipopolysaccharides) are formed when Gram-negative bacteria decay and are also released in the gastrointestinal tract of animals and excreted with the faeces. They attach themselves to dust particles and can be partly responsible for respiratory diseases and restrictions of lung function in humans as well as animals. The project aims to further reduce endotoxins and particulate matter with the goal of contributing to a healthier living environment for people and animals in the stables as well as for local residents. For more information, see www.belair-project.eu.

BEL AIR is being implemented within the framework of the INTERREG V A programmes Deutschland-Nederland and is co-financed by the European Regional Development Fund (ERDF) and the Dutch Ministerie van Economische Zaken en Klimaat, the Ministry für Wirtschaft, Innovation, Digitalisierung und Energie des Landes Nordrhein-Westfalen and the provinces of Gelderland, Limburg and North Brabant. It is accompanied by the programme management at the Euregioder Euregio Rhein-Waal.