BEL AIR: Project on endotoxin emissions from poultry houses

In the framework of the German-Dutch INTERREG project BEL AIR, solutions for clean and healthy air at poultry farms are tested and developed to prevent health risks caused by fine dust and endotoxin emissions. Eleven partners – companies and organizations from the German-Dutch border region – have joined forces for this purpose and are being guided through the four-year project by the lead partner GIQS e.V.

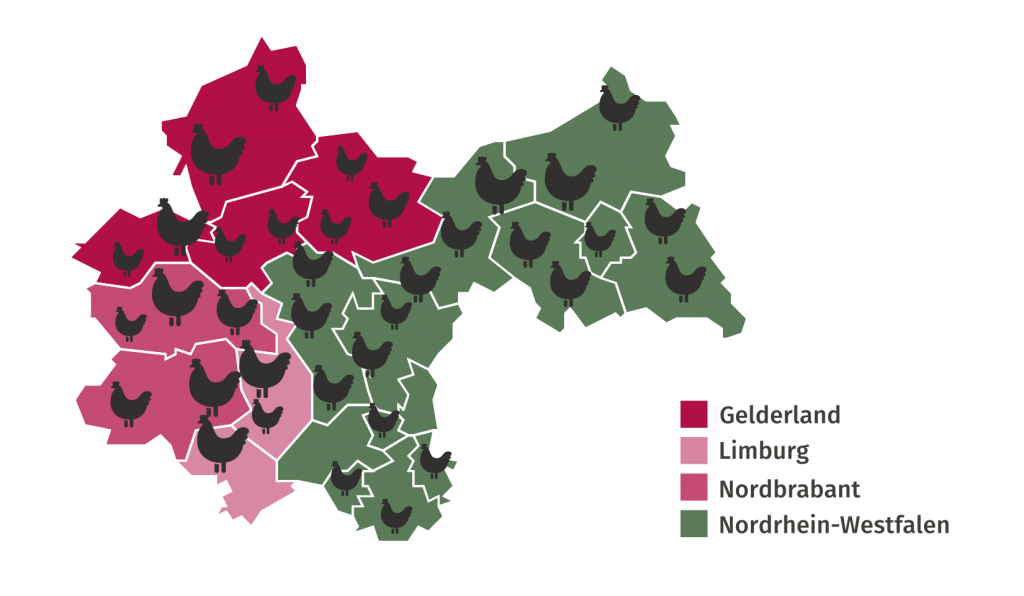

The German-Dutch border region is the European leader for the poultry industry and also an important address internationally. The majority of the fattening farms in both countries are then also concentrated in the border region. There are more than 2,000 poultry farms in the entire Netherlands, and 65,000 farms in the whole of Germany – 800 of which are very large. Worldwide demand for poultry products has been growing continuously for years, which is why meat and processed products from the border region are exported all over the world. But another trend can also be discerned: for example, the number of animals kept per farm in the Netherlands has doubled since the turn of the millennium, while the number of farms has halved, which means fewer but larger barns with higher stocking rates.

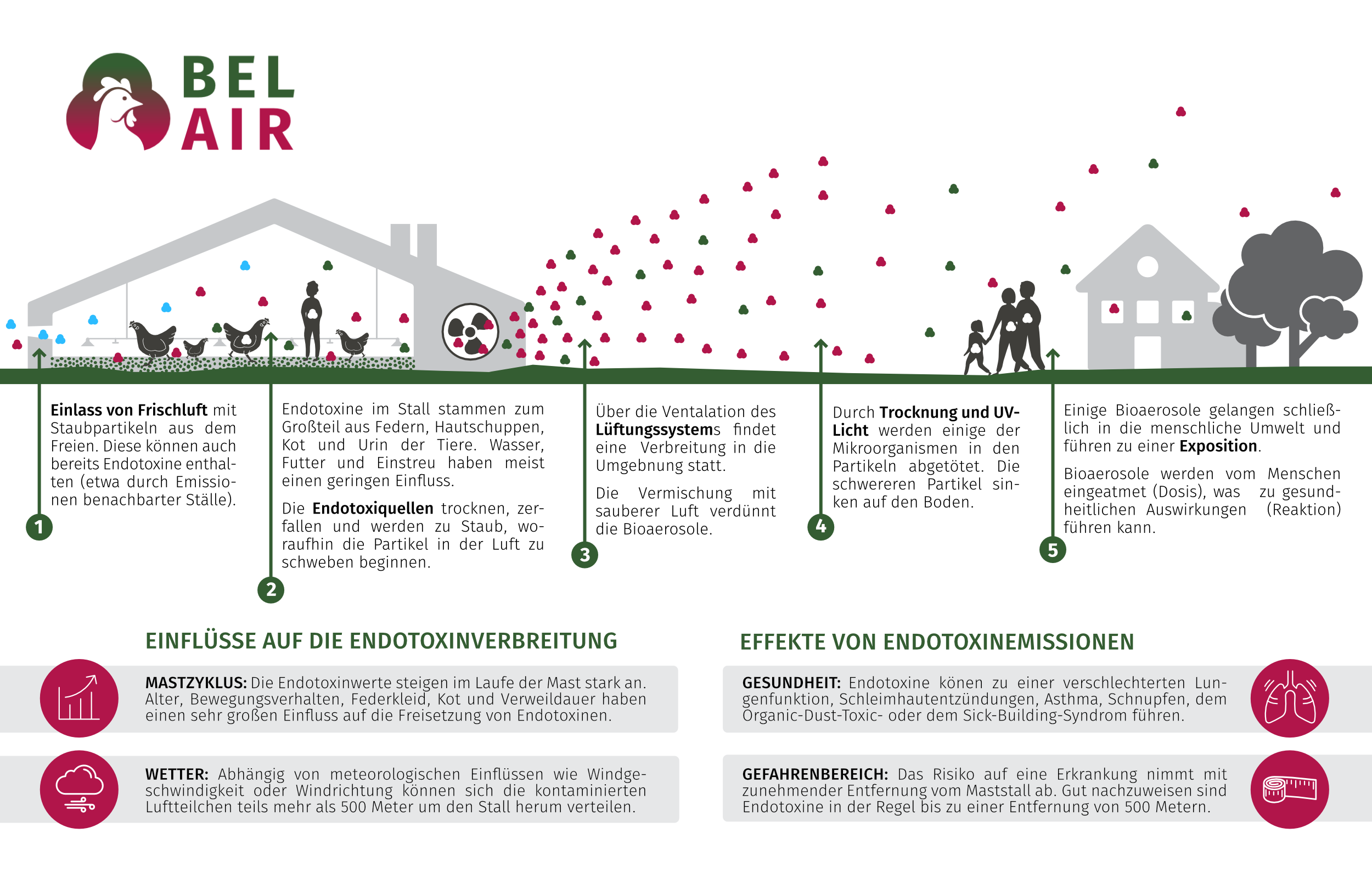

Sufficient ventilation is essential for the operation of livestock houses in order to supply the animals with sufficient oxygen, to regulate the house temperature in particularly warm or cold outside temperatures, and to remove particles and toxins from the house. Health risks for the animals themselves, for barn workers as well as for residents around the farms result in particular from bioaerosols, biotoxins, germs and inhalable dusts, which are very concentrated in the barn air of chicken fattening facilities. However, depending on meteorological influences such as wind speed and wind direction, the contaminated air particles can spread as an organic dust cocktail sometimes more than 500 meters around the fattening farm. Since 40,000 animals are no longer uncommon in poultry fattening, the volume of air that is moved through the ventilation system is also very considerable.

Health risk for residents

In the Netherlands in particular, livestock farms are often located at a relatively short distance from residential buildings – 70 to 90 percent are even less than 250 meters away from a residential development. In the southern province of North Brabant, it is estimated that 7.5 percent of residents live less than 250 meters from a livestock farm. In the case of poultry farms, there are almost one million inhabitants in the entire Netherlands who live within a radius of less than one kilometer from such farms.

Various epidemiological studies indicate a health risk for people living in the vicinity of fattening facilities as well as agricultural personnel in intensive livestock farming. The focus is particularly on the so-called endotoxins (lipopolysaccharides). These are components of the cell wall of certain (Gram-negative) bacteria such as Salmonella, Pseudomonas or E. coli, which are formed when the bacteria decay. They are also released in the gastrointestinal tract of animals and excreted in the feces. Unlike the bacteria themselves, endotoxins are very resistant to external influences and can remain active for years. Unless they attach themselves to larger dust particles, they often remain in suspension – as a bioaerosol coupled to fine dust particles, for example – for a very long time and can still be detected in the ambient air of fattening stables for a long time to come.

In the human body, endotoxin exposure can manifest itself, for example, in respiratory diseases such as deteriorated lung function, mucosal inflammation, asthma, rhinitis, organic-dust-toxic syndrome or sick-building syndrome. The risk of disease decreases with increasing distance from the fattening house. Endotoxins are generally easily detected up to a distance of 500 meters from the barn, which means that people who are within this radius or even directly in the barn are particularly at risk. These concrete health hazards caused by endotoxins are also indicated by the findings of the agricultural employers’ liability insurance associations, where an increasing number of applications for occupational disability have been filed by workers in fattening farms in recent years.

Citizen protests against fattening farms

Residents living in the vicinity of large fattening farms are also increasingly concerned about their health and are taking to the streets. Protests against intensive livestock farming have always been and continue to be more frequent when new fattening facilities are built or existing barns are to be expanded. Particularly in areas with a high density of stables, citizens’ initiatives have been forming on both sides of the border for several years and are seeking legal action against farmers’ building permits. The larger the barns become, the quicker public protest arises – for example in the case of the so-called “mega barns”.

Recent studies from Germany and the Netherlands on the impact of livestock house emissions on local residents have led to stricter legal limits, particularly in the Netherlands, which are to take effect from 2027. Existing fattening farms will then have to reduce their emissions of particulate matter (and thus also endotoxins) by 50 percent – new buildings will have to emit as much as 70 percent less particulate matter. In the Dutch province of North Brabant, whose southeastern region is known for the highest livestock density in Europe, plans were made for an even faster sustainability process in animal husbandry. And on the German side of the border, some districts in Lower Saxony are already demanding expert opinions on the subsequent spread of germs into the surrounding area in application procedures for large-scale fattening facilities.

BEL AIR aims to combat endotoxin at source

It is precisely this challenge, the development of technologies and measures for lower or less hazardous emission levels from poultry houses, that the BEL AIR project is addressing with its activities, in which a total of twelve project partners are (further) developing and testing various technologies for reducing particulate matter and endotoxin emissions in and outside poultry houses.

In contrast to the state of the art, BEL AIR’s focus is less on downstream “end-of-pipe” technologies that – like filtration systems – sequester hazardous particles just before the house air is released into the environment. They have the disadvantage that the fine dust that has already been created and contaminated with endotoxins has to be removed from the air again in a cumbersome manner, resulting in additional acquisition, energy, maintenance and servicing costs for the farmer. The BEL AIR partners, on the other hand, focus more on where the endotoxins originate and try to influence their formation and spread there. In this way, animals and stable workers can also be better protected from the influence of fine dust and endotoxins. For more information, visit www.belair-project.eu.

BEL AIR is being implemented within the framework of the INTERREG V A programmes Deutschland-Nederland and is co-financed by the European Regional Development Fund (ERDF) and the Dutch Ministerie van Economische Zaken en Klimaat, the Ministry für Wirtschaft, Innovation, Klimaschutz und Energie des Landes Nordrhein-Westfalen and the provinces of Gelderland, Limburg and North Brabant. It is accompanied by the programme management at the Euregio Rhein-Waal.